HDD Engineering DNA

Ultra-Narrow Fabrication

Active Calibration Mastery

STABILITY THROUGH

SYSTEM-LEVEL INSIGHT

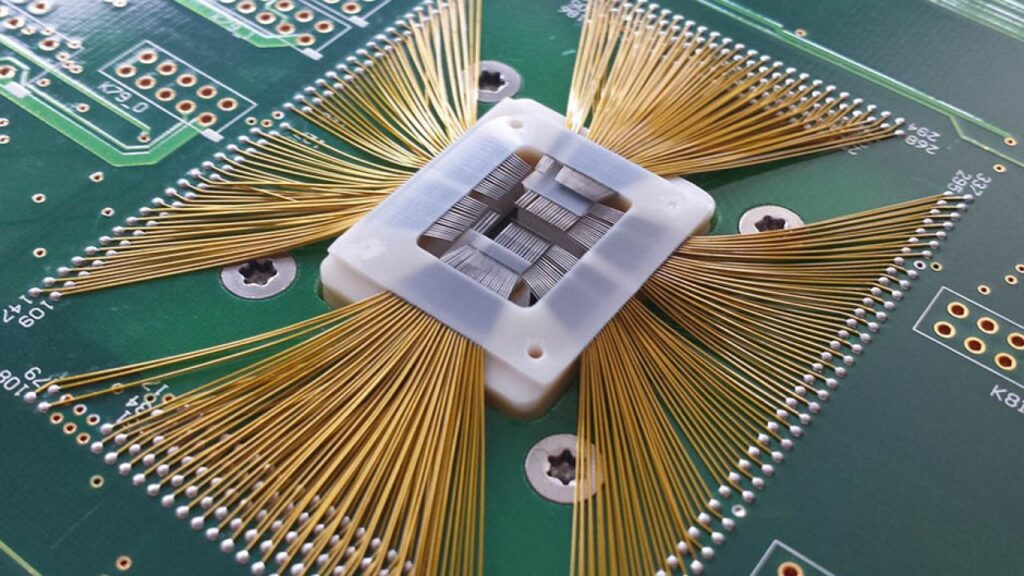

Our fabrication excellence is rooted in our deep mastery of the test environment. By re-engineering thermal burn-in systems for maximum uniformity, we gained the thermal-mechanical insights required to build stable 20μm probe card architectures that perform flawlessly under extreme stress.

SPECIALIZED PROBE CARD

BUILD-TO-PRINT PROCESSING

- 🚀 20μm Ultra-Narrow Pitch: Micron-level alignment accuracy.

- 🚀 Logic & Memory Focus: High-density interconnect processing.

- 🚀 Structural Reinforcement: High-voltage & large-current stability.

- 🚀 100% IP Security: Pure contract manufacturing focus.

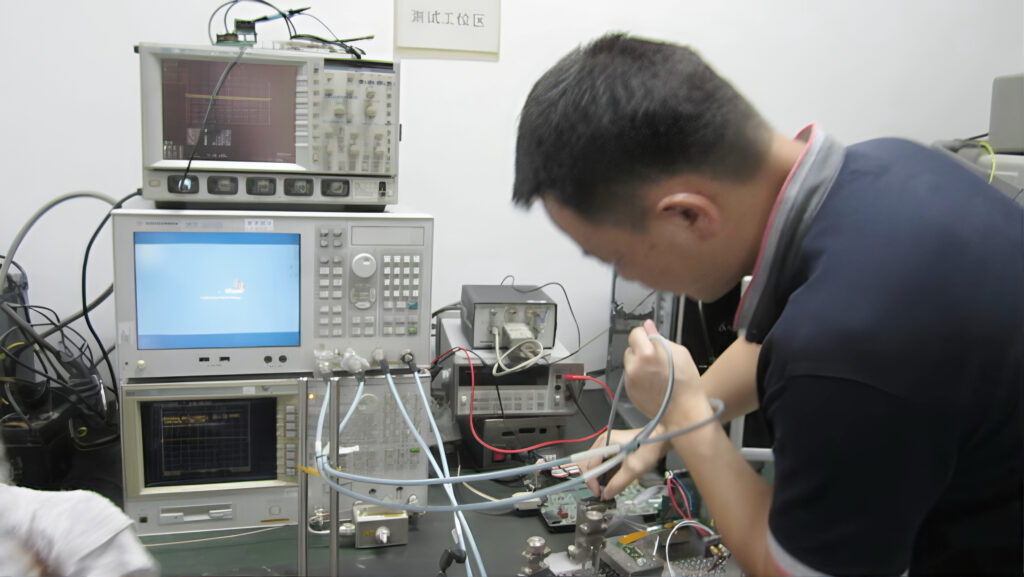

ACTIVE CALIBRATION:

OPTIMIZING SILICON PERFORMANCE

Utilizing full-stack Agilent (Keysight) systems, we don’t just verify signals—we write optimization parameters directly back to chip registers, ensuring 100% functional alignment for Flip Chip assemblies.

Foundational

Manufacturing

Building on our roots since 2003, we maintain high-reliability in-house capabilities for agile lamination, specialized ESD coatings, and high-precision soldering.

READY TO EXECUTE YOUR

NEXT-GEN TEST INTERFACE?

Consult with our engineering team for specialized Build-to-Print processing and Agilent-verified calibration.